Hot Tap & Line Stopping Services in North America

Companies are often required to make modifications to their existing process piping systems and containment tank systems for reasons of expansion or maintenance. Historically, this has required shutting down a portion of the system and purging the line to ensure a safe connection. Hot tapping & Line Stopping is a cost & time-efficient alternative procedure of making connections to in-service piping systems, tanks and vessels.

Safe from start to finish, Taurus Industrial Group and Red Flame Industries’ are committed to risk management, through engineering controls, uncompromising standards, and complete hot tap & line stopping services, with custom designed solutions.

-

Turn-Key Hot Tap Projects

-

Hot Tap Capabilities

-

Cold Tap Projects

-

Line Stopping

Turn-Key Hot Tap Projects

Hot Tap Project Development from Start to Finish

Customized Hot Tap Design

Specialized Tooling

Metallurgical & Mechanical Design

In-House Manufacturing

In-Service Welding Procedures/Welders For All Applications

In-House NDT (Non-destructive Testing)

Quality Control Documentation

HAZOPS & Permit Administration

Compliance With Applicable CSA Or ASME Codes

In-House Engineering and design package submissions to meet all ASME Provincial Regulatory bodies (with exception of Quebec)

HOT TAP CAPABILITIES

Capabilities

Hot Tap Branches 0.25” to 48” Outlet

Pressures Up To 5,000 PSI (35,000 kPa)

Design Temperatures up to 371 °C (700 °F)

Branch and Tap Types

Branch Reducing Hot Taps

Olet (Weldolet, Sockolet, Threadolet)

Split Tee (Size on Size Application)

Tank Nozzle & Repad Outlets

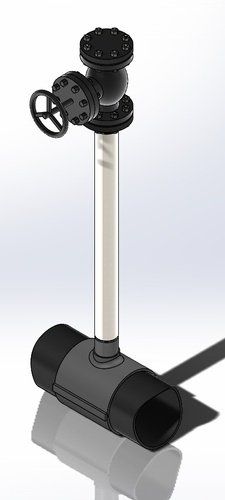

Extended Reach/Below Grade Riser Applications

Riser Applications up 6.1m or 20’ Depth for branch connections 2” to 8” Diameter

Branch Diameters 10” and Greater up to 3.5m or 10’

Red Flame Pro (Pig) Bar System if required

Valve Drill Out

Thermowell, Pig Signal, or Injection Nozzles

COLD TAP PROJECTs

-

Mechanical Cold Tap Connection For Pressure Confirmation and De-Pressurizing.

Applicable to Pipeline, Drilling Pipe, Well Head/ Well Piping, Coil Tubing and more!

-

Perform Branch Taps without purging stagnant or line contained fluid or gas.

-

Cold Tap Pressure Verification, Migration Testing, NORMS Testing, Cold Cutting, Cap Installation and Tag Labeling.

-

Cold Tap Pressure Verification, NORMS Testing, Cold Cutting, Cap Installation and Tag Labeling.

-

Bolt On Branch Fittings for Temporary or HDPE/PVC Branch Connections

LINE STOPPING

Capabilities

High Pressure Systems - Size: 2” up to 24” (Pressure: 750 PSI / 5171 kPa)

Low Pressure Systems - Size: 3” up to 72” (Pressure: 100 PSI / 690 kPa

Temperatures - 0 °C to 242 °C (32 °F to 462 °F)

Line Stop Types

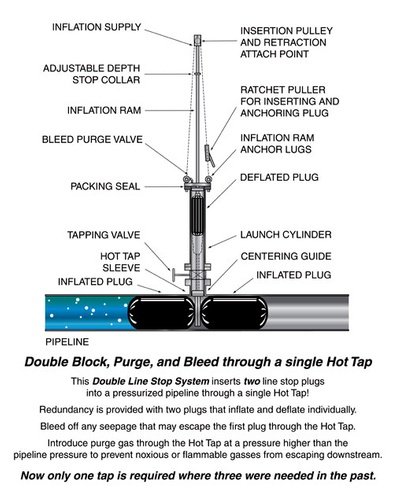

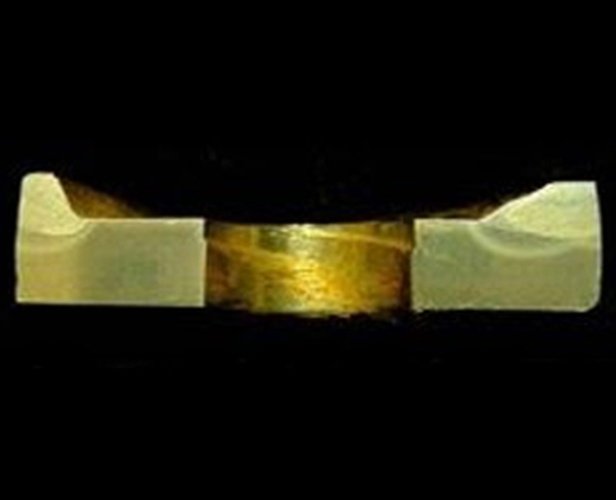

Low Pressure Kevlar Isolation Bag System - Single and Double-Block-and-Bleed

Low Pressure Short Stop Sealing Cup Applications

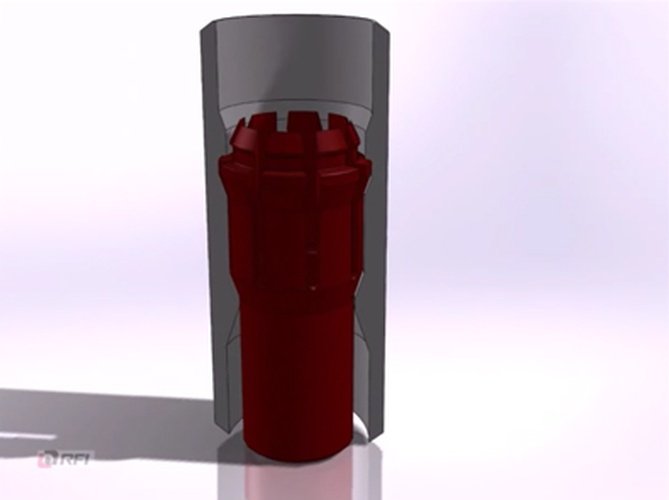

High Pressure Pivot Head Line Isolation System - Single and Double-Block-and-Bleed

High Pressure Single Port Double-Block-and-Bleed System

Additional Items to Suit Line Stop Requirements

Continued Flow By-Pass Capabilities

Built to Suit Your Flow and Pressure Requirements

Red Flame No-Leak Pro-Plug Flange Completion System

◦ Bury your pipeline with a sealed and blinded line stop connection you can trust

Need Help With A Project?

contact our

team today!

Browse our Hot Tap & Line Stopping Videos

Extended Reach

Hot Tap

Bag Linestop